News

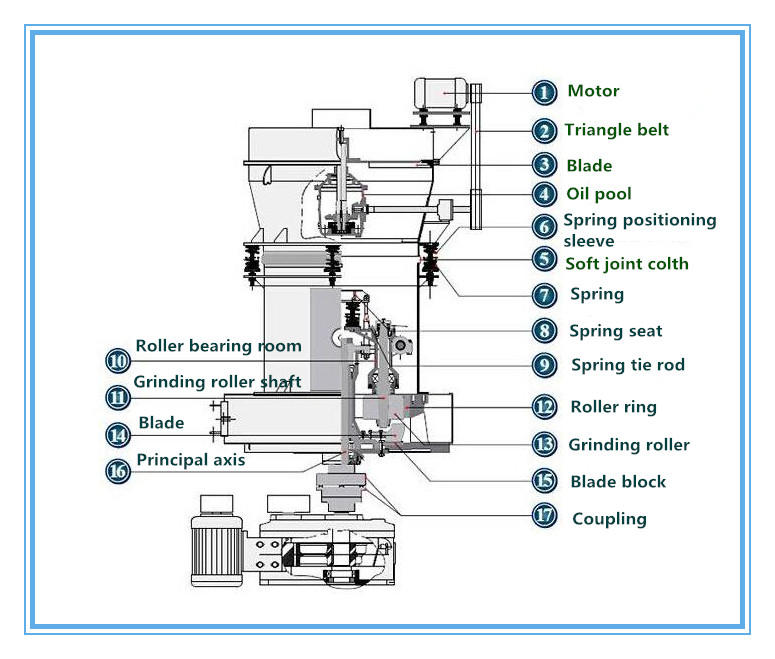

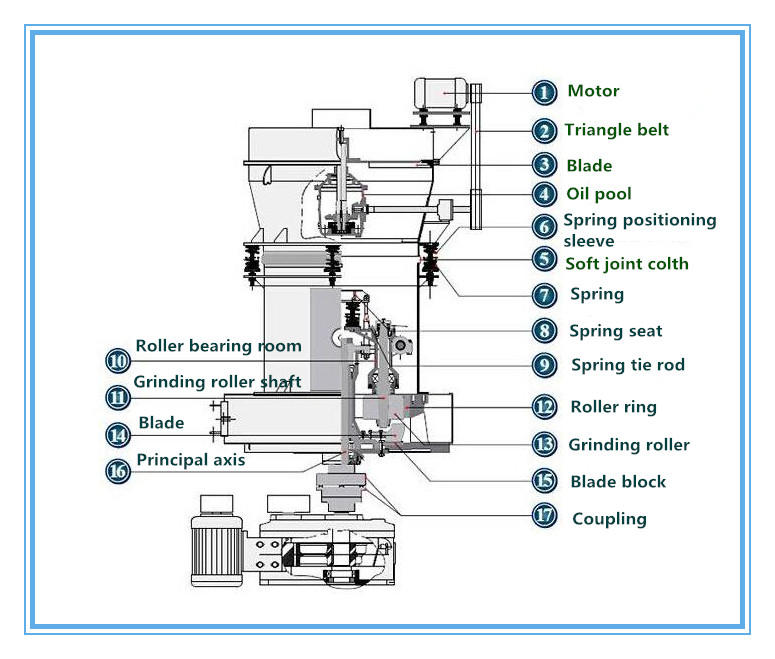

Ultra-fine Powder Mill Accessories

Date:2021-08-27 06:29:55

The ultra-fine powder mill is composed of different parts. In the grinding operation of materials, these parts cooperate with each other to keep the equipment in normal operation, so as to realize the grinding and milling of materials. Here, we will give you a brief introduction to the common accessories of ultra-fine powder mills.

1. Grinding roller and grinding ring

In the ultrafine powder mill, the grinding roller grinding ring is the main grinding part, and it is also one of the more vulnerable parts. Under normal circumstances, the material of the grinding roller ring is high manganese steel wear-resistant material. However, because the materials ground by the ultra-fine pulverizer have greater hardness, with the operation of the equipment, a strong external force threatens the service life of the grinding roller and grinding ring. These parts are usually repaired and replaced regularly. Ensure the smooth progress of the milling operation.

2. Shovel

When the ultra-fine powder mill grinds the powder, the blade is the main carrier of the material. It scoops up the material entering the grinding chamber and throws it between the grinding roller and grinding ring at a certain angle. It is one of the parts that directly contact the material. Therefore, in order to ensure the quality of the milling equipment, the blade is generally required to have strong wear resistance.

3. Transmission

In the ultra-fine powder mill, the bevel gear transmission is a major feature. Under normal circumstances, the bevel gear is the channel through which the entire motor energy is transmitted, and its transmission effect directly affects the production results of the milling equipment. Therefore, the requirements for lubrication of bevel gear transmission are quite strict.

4. Grinding roller shaft and bearing

The grinding roller shaft and bearing connected between the grinding roller and the plum blossom frame are also important transmission devices. In the process of ultra-fine powder grinding mechanism, if the equipment is used improperly, or the ultra-fine powder mill is in an overloaded operation state for a long time, the bearing part is lack of lubricating oil, etc., it is easy to cause the whole machine to lock up.

5. Analysis machine, fan blades

Blades are installed inside the analyzer and fan of the ultrafine powder mill, which play a role in rotating powder selection for the grinding operation. Although these parts are not easy to wear, they will be damaged to varying degrees with the extension of working time, which will affect the grinding effect. Therefore, the analyzer and fan blades also need to be overhauled and updated regularly.

CLIRIK provide solutions for grinding/crushing and screening

The common choice of 1000+ customers, tailor-made solutions for you

More than 30 years of experience in R&D and manufacturing, and 120+ countries and regions coverage to jointly witness high-quality quality

Systematic and standardized process, safer and more efficient from service to preparation and delivery

Finished product analysis-project declaration-process design-material trial grinding-infrastructure guidance-installation and commissioning-training guidance-project acceptance-after-sales service

Here are 4 reasons to choose CLIRIK

1. Factory direct supply

The source manufacturer has no middleman, higher cost performance, large quantity and excellent quality, ingenuity

2. Ingenuity

Automatic equipment production, the pipe wall is thicker and resistant to compression and deformation, environmentally friendly materials are harmless, and support customization

3. Support customization

Can be specially designed according to customer requirements, support various environmental program customization, strictly inspect the quality before leaving the factory, and improve the service

4. Perfect service

One-stop pre-sales and after-sales service, on-site survey, on-site installation, 7x24 hours after-sales service

CLIRIK business areas

1. Industrial milling

Grinding particle size: covering 0-3mm coarse powder; 20-400 mesh fine powder; 400-3250 mesh superfine powder

2. Gravel aggregate

Crushing field: various soft, medium and hard ores; coarse crushing/medium crushing/fine crushing, sand making, sand washing, feeding, screening, conveying, etc.

3. Various ores

Application: various soft, medium and hard metal ore crushing, conveying, grinding, powder selection, powder collection, dust removal, packaging, automatic control, etc.

4. Building materials

Building materials field: tailor-made solutions and high-quality supporting equipment provide green, environmental protection and high added value.

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829

Product List