Powder Mill

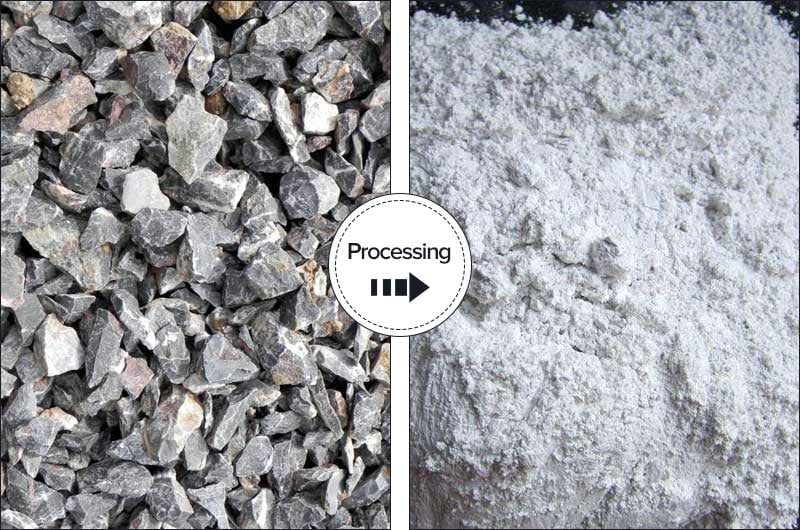

Limestone powder grinding mills

The main component of limestone is calcium carbonate (CaCO3). Lime and limestone are a large number of raw materials used in construction materials and industries.

Application fields of limestone powder grinding mills:

High-fine powder processing of more than 280 materials in mining, metallurgy, chemical, building materials and other industries.

Applicable materials for limestone powder grinding mills:

Quartz, feldspar, calcite, limestone, talc, ceramics, marble, granite, dolomite, bauxite, iron ore, barite, bentonite, coal gangue, coal and other materials.

How to choose a limestone powder grinding mill?

- Within 200 mesh limestone powder: Raymond mill, high pressure mill

- 250 mesh -300 mesh limestone powder: Raymond mill, high pressure mill

- 300 mesh-1250 mesh limestone powder: high pressure mill, HGM superfine mill, CLUM superfine vertical mill

- 1250 mesh-3000 mesh limestone powder: HGM ultra-fine mill, CLUM ultra-fine vertical mill

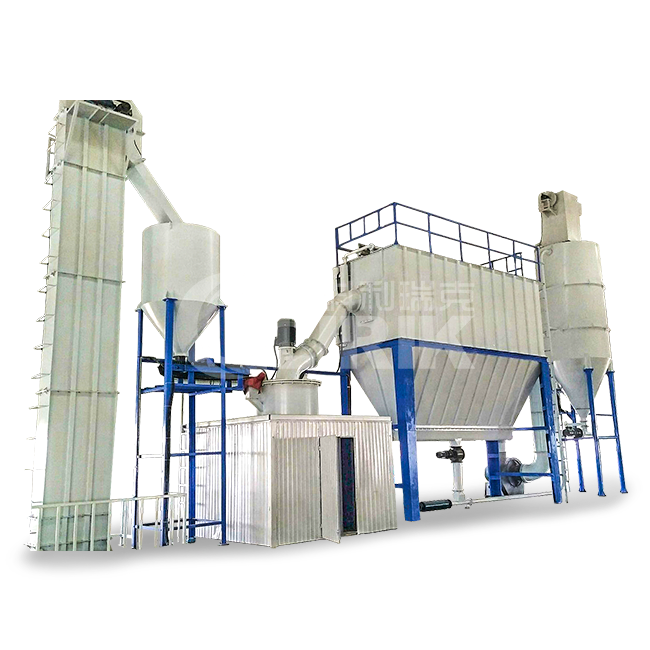

Commonly used limestone powder grinding mills

The particle size of the finished limestone powder grinding mill is between 80 mesh and 3000 mesh. There are many types of limestone powder grinding mills. Commonly used are limestone ball mills, limestone Raymond mills, limestone ultrafine mills, limestone high-pressure mills, and limestone ultrafine vertical mills.

1. Limestone Powder Raymond Mill

Output: 8-78t/h,

Feed size: ≤25mm,

Discharge size: 80-325 mesh,

Features: The machine has a stable transmission, reliable operation, a through-screen rate of up to 99%, uniform fineness of the finished product, and less impurities. The material of the wearing parts is high manganese steel, and the service life is long.

2. Limestone Powder High Pressure Mill

Output: 1-20t/h,

Feed size: ≤15mm,

Discharge size: 80-425 mesh,

Features: The equipment is small in size and adopts PLC electrical automation control, which effectively reduces the failure rate of the equipment. The grinding rollers and grinding rings are strong and wear-resistant, long service life, large output, and output increased by 10-20%; simple structure and convenient operation.

3. Limestone powder ultrafine mill:

- Output: 0.5-45t/h,

- Feed size: ≤20mm,

- Discharge size: 400-2500 mesh,

- Features:

1. Low noise and low vibration.

2. Lida (21 grinding rollers, three-layer grinding roller ring groove), with a lot of fine powder.

3. The grinding ring and grinding roller wear uniformly and have a long service life, which is 3-5 times that of ordinary Raymond grinding.

4. Suitable for the processing of hard materials.

5. The iron content in the micropowder is small.

6. The output of fine powder is high, and it can be operated continuously without affecting the oil filling of the spindle bearing chamber during operation.

7. Low power consumption, high efficiency, convenient installation and maintenance.

4. CLUM ultrafine vertical mill:

- Output: 3-20t/h,

- Feed size: ≤10mm,

- Discharge size: 400-3000 mesh.

- Features: The powder produced by this equipment has high fineness and good sphericity, which is suitable for the manufacture of high-end superfine powder.

The working principle of limestone powder grinding mills

Different limestone powder grinding mills have different working principles. The specific introduction is as follows:

1. The working principle of limestone Raymond mill

When the limestone Raymond mill is working, the material that needs to be crushed is fed into the machine from the feeding hopper on the side of the machine casing. It relies on the grinding roller device hanging on the plum blossom frame of the main machine to revolve around the vertical axis and rotate itself at the same time. When rotating, the centrifugal force causes the grinding roller to swing outwards and tightly press on the grinding ring, so that the shovel blade scoops up the material and sends it between the grinding roller and the grinding ring. The material is crushed due to the rolling and rolling of the grinding roller.

2. The working principle of limestone micro-powder mill

When the micro powder mill is working, the main machine drives the main shaft and the turntables of each layer to rotate through the reducer, so that dozens of ring rollers roll and rotate in the grinding ring raceway. The bulk material is crushed to the required size by the crusher, and then sent to the storage bin by the elevator, and then sent to the middle of the upper turntable uniformly, quantitatively and continuously by the vibrating feeder. The material is dispersed under the action of centrifugal force. The periphery, falling into the raceway of the grinding ring, is crushed by the ring rollers, stamped, rolled, and ground. After the first layer is crushed, the material falls into the second layer for finer grinding, and then enters the third layer of grinding. , So as to achieve the required particle size.

3. The working principle of limestone ultra-fine powder grinding mill

In the main grinding chamber of the ultrafine mill, the grinding roller assembly is suspended on the grinding roller hanger through the cross arm shaft. The grinding roller hanger is fixedly connected with the main shaft and the blade holder. The pressure spring is tightly pressed against the grinding roller by the tension rod. On the outer end of the cantilever of the roller bearing chamber, with the cross arm shaft as the supporting point, the grinding roller is pressed tightly on the inner surface of the grinding ring by spring pressure. When the motor rotates through the transmission device, the shovel mounted on the shovel holder The knife and the grinding roller rotate synchronously. The grinding roller rotates around itself while rolling on the inner surface of the grinding ring. The analyzer drives the analyzer impeller to rotate through the motor transmission device. The rotation speed of the analyzer determines the fineness of the powder.

4. Limestone three-ring medium-speed micro-powder mill

When the three-ring medium-speed micro-powder mill is working, the main machine drives the main shaft and each layer of the turntable to rotate through the reducer, so that dozens of ring rollers roll and rotate in the grinding ring raceway. The bulk material is crushed to the required size by the crusher, and then sent to the storage bin by the elevator, and then sent to the middle of the upper turntable uniformly, quantitatively and continuously by the vibrating feeder. The material is dispersed under the action of centrifugal force. The periphery, falling into the raceway of the grinding ring, is crushed by the ring rollers, stamped, rolled, and ground. After the first layer is crushed, the material falls into the second layer for finer grinding, and then enters the third layer of grinding. , So as to achieve the required particle size. At this time, the suction effect of the high-pressure centrifugal fan sucks the outside air into the machine, and brings the powder after the third layer of pulverization into the powder concentrator. The vortex generated by the rotating worm wheel in the classifier makes the coarse particles fall back and regrind, and the fine powder enters the cyclone powder collector with the airflow and is discharged by the discharge valve at the lower part of the product.

Precautions for purchasing limestone powder grinding mill:

- 1. Output size: There are many models of stone mills, and the output of different models is different. It is necessary to choose the output size suitable for the production site. The price of different output is different.

- 2. Energy saving and environmental protection: Whether the equipment is energy saving and environmental protection is the point we need to pay attention to when purchasing equipment. At present, the country has strict environmental protection inspections, and the equipment must pass the environmental protection pass before it can be put into production.

- 3. Equipment quality: Quality is the issue we pay more attention to when we buy equipment. Quality is related to its operating efficiency and subsequent maintenance costs. The better the quality, the higher the work efficiency, the higher the profit, and the higher the equipment price.

Who we are?

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829

Inquiry:

Product List