Products

Ground Calcium Carbonate Powder Surface Modification Machine

The surface modification technology of ground calcium carbonate is mainly through the addition of surface modifiers for surface chemical treatment. Surface modification should be carried out with the help of equipment: Ground Calcium Carbonate Powder Surface Modification Machine.

The commonly used surface modification equipment is the CLG continuous powder surface modification machine.

Ground Calcium Carbonate Powder Surface Modification Machine

Why should the surface of ground calcium carbonate powder be modified?

Ground calcium carbonate (GCC, heave calcium carbonate) processed with calcite, limestone and chalk is currently the largest amount of inorganic filler in organic polymer-based materials.

However, the untreated ground calcium carbonate has poor compatibility with the polymer, which is likely to cause uneven dispersion in the polymer base material, resulting in interface defects of the composite material and reducing the mechanical strength of the material.

As the dosage increases, these shortcomings become more obvious. Therefore, in order to improve the application performance of the ground calcium carbonate filler, it must be surface modified to improve its compatibility or affinity with the polymer base.

Surface modifier for ground calcium carbonate powder

The surface modification of ground calcium carbonate is mainly through the addition of surface modifiers for surface chemical treatment. The main surface modifiers used are: stearic acid (salt), titanate coupling agent, aluminate coupling agent, zirconate aluminate coupling agent, random polypropylene, polyethylene wax, etc.

Surface Modifier of ground calcium carbonate

Surface modification should be carried out with the help of equipment. Commonly used surface modification equipment are CLG type continuous powder surface modifier (Figure 1), high-speed heating mixer (Figure 2), eddy current mill and fluidized modifier, etc.

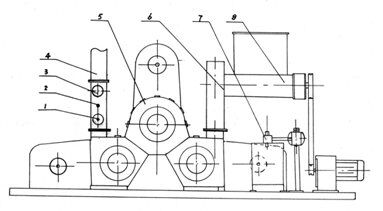

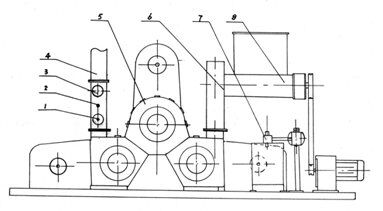

Figure 1 CLG type continuous powder surface modifier

1- Thermometer; 2- Outlet door; 3- Air inlet; 4- Air duct; 5- Host; 6-Inlet port; 7- Metering pump; 8- Feeder

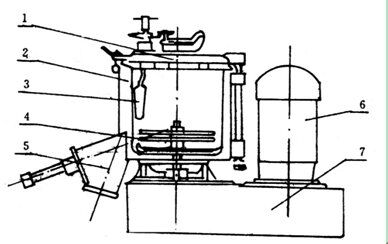

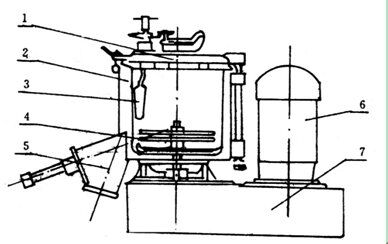

Figure 2 High-speed heating mixer

1- Rotary cover; 2- Mixer; 3- Baffle plate; 4- Stirring impeller; 6- Drive motor; 7- Base

1- Rotary cover; 2- Mixer; 3- Baffle plate; 4- Stirring impeller; 6- Drive motor; 7- Base

Specifications of CLG powder surface modification machine

| Model | Main Power | Blower Power | Speed of Shaft | Capacity | Weight | Overall Dimension |

|---|---|---|---|---|---|---|

| CLG-200D | 11kw | 2.2kw | 5700 r.p.m | 40-150kg/h | 1t | 3200*600*2200mm |

| CLG-3/300 | 3-18.5kw | 5.5kw | 4500 r.p.m | 500-1800kg/h | 3t | 5800*1800*5600mm |

| CLG-3/600 | 3-37kw | 15-22kw | 2700 r.p.m | 2000-4000kg/h | 10t | 11200*3100*6200mm |

| CLG-3/900 | 3-75kw | 45kw | 2000r.p.m | 4000-7000kg/h | 20t | 21000*3800*6500mm |

Modification process of ground calcium carbonate

After the calcium carbonate is dried (the dry powder with lower moisture content may not be dried), it is fed into the surface modifier, and a certain amount of surface modifier is added at the same time. After acting for a certain period of time, the surface modified active heavy carbonic acid can be obtained calcium.

What are the factors that affect the surface modification effect of ground calcium carbonate?

The main factors affecting the surface modification effect of ground calcium carbonate are:

1. The variety, dosage and usage of the surface modifier (the so-called surface modifier formula);

2. Surface modification temperature and residence time (namely surface modification process);

3. The degree of dispersion of surface modifiers and materials, etc.

Among them, the degree of dispersion of surface modifiers and materials mainly depends on the surface modifier.

How to choose a powder surface modifier?

Surface modifier formulation is the key technology for surface modification of ground calcium carbonate. When choosing a surface modifier formulation, first consider the application system of modified ground calcium carbonate, secondly, consider the particle size, distribution characteristics and specific surface area of ??ground calcium carbonate, and also consider the cost of the surface modifier.

How to choose a powder surface modification machine?

After the formula is determined, the surface modification equipment must be selected. Good surface modification equipment should have the following basic process characteristics:

1. Good dispersibility for powders and surface modifiers

2. Equal opportunities for contact or action between powder and surface modifier

3. Modification temperature is adjustable

4. Low energy consumption per unit product

5. No dust pollution

6. Simple operation and stable operation

Inquiry:

Product List