News

Standard operation and daily maintenance measures of quartz sand grinding mill

Date:2022-06-14 16:57:43

With the development of the mining industry, the quartz sand grinding mill has a good momentum of development in recent years, and now it has become a commonly used grinding equipment for grinding users.

So what are the standardized operations and daily maintenance measures of the quartz sand mill when it is used?

1. Operate the quartz sand mill in strict accordance with the milling requirements. First adjust the rolling distance before driving, and then adjust the rolling distance to normal after the material enters.

2. The power of the quartz sand mill is large, and the power can be doubled with the change of the rolling distance, so it is necessary to pay more attention to the tightness of the transmission belt.

3. Before starting the quartz sand mill, the debris inside and around the machine should be removed, and the parts should be rotated by hand to check the tension of the V-belt and the chain, whether the fasteners are firm, and whether the lubrication is normal.

4. The belt of the quartz sand mill deviates and slips on the pulley. It can be solved by looking at it frequently and finding it from the smell, and can take the method of sprinkling rosin on the belt and loosening the gap properly. If a beating sound is heard, it means that the belt is partially disengaged and the head is thrown, and the machine should be stopped immediately for repair.

5. Failure of the bearing of the quartz sand mill. Look for worn bearings or bushings, cracked bearings, and improperly installed rollers. If there is a problem with the end of the bearing swinging, it may be that the elastic force of the rolling distance adjusting mechanism is insufficient or the grinding roller is unbalanced. If the bearing has oil rejection, the bearing should be re-adjusted and a suitable washer should be installed to prevent grinding the roller shaft. move to.

6. The grinding rollers of the quartz sand mill should be replaced one by one in a planned way. Do not replace a large number of new drawing rollers at the same time, so as not to cause a drastic change in the process effect.

7. The quartz sand mill keeps the suction pipe unobstructed, and regularly checks and removes the accumulated powder in the pipe.

8. If the gear noise is too large, the reasons can be found from the inclination of the gear device, the imbalance between the grinding roller and the transmission wheel, the lack of lubricating oil, the incorrect tooth shape or excessive wear and so on.

9. When the quartz sand mill is grinding, the material should be evenly distributed on the entire length of the grinding roller. When the incoming material decreases or the feeding is suddenly stopped, the grinding roller should be released immediately to prevent damage to the machine.

Quartz Sand Grinding Mills Manufacturer-CLIRIK Machinery

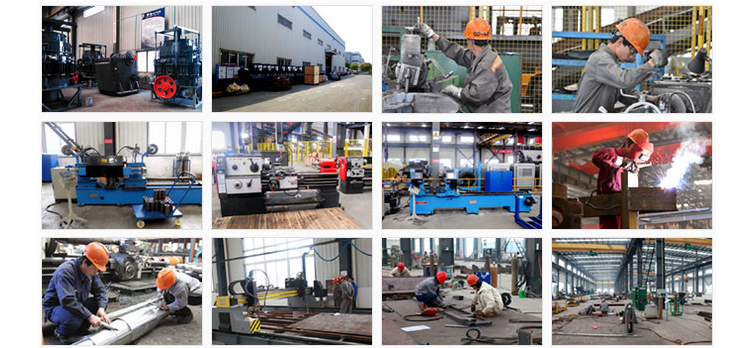

The ore crushing production line designed by Shanghai Clirik Machinery Co., Ltd. is a large-scale ore production line manufacturer. Professionally provide high-quality quartz sand grinding mills.

Well received and trusted by customers. CLIRIK provides services such as on-site installation of ore production line equipment and free trial machine.

Quartz sand grinding mill supplier

Turnkey projects

CLIRIK specializes in the production of ultra-fine mills and has a professional R&D, production, sales and after-sales team. Provide you with a full set of services from production line design to on-site installation.

R & D design

CLIRIK has a technical research and development team of more than ten people, and holds a number of design patents. CLIRIK continuously improves equipment performance according to changes in the market and customer needs. Provide you with quality products that keep pace with the times.

Quality assurance

CLIRIK mill products have CE, ISO and other quality certifications, and third-party testing agencies test the quality, so you can rest assured.

Strategic location

The CLIRIK factory is located in Shanghai’s Pudong New Area, only one hour’s drive from Yangshan Port, the largest port in Shanghai. Convenient delivery, only half an hour's drive from Shanghai Pudong International Airport. It is convenient for customers to get on and off the bus.

Local customer site, more intuitive

As an export manufacturer with more than ten years of experience, CLIRIK has its own customer sites in many countries for you to visit.

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829